Whatever became of Sanitation Sally?

Whatever became of Sanitation Sally?

Since 2011, Lisa Smyth has been working on the front lines of sanitation reform in Haiti – an under-addressed issue, she confessed in a project post by Architecture for Humanity. Waste is a hard enough thing to discuss publicly, let alone address earnestly. Yet there was promise – a sanitation summit on Sustainable Sanitation in Haiti was organized by local organization Sustainable Organic Integrated Livelihoods (SOIL) in June 2012, and enough time now has passed that we might be able to examine today’s discussion and the progress made.

Lisa now works for Islamic Relief, managing the school design and construction program(me), but never far from the conversation and advocacy around sanitation systems – absolutely clean, and as sustainable as the schools themselves can manage. I caught her on a working Saturday and downloaded the latest on design practices for treating waste in Haiti’s schools…

(To know going in: Islamic Relief and others working in these issues work closely with DINEPA, the National Bureau of Water and Sanitation of Haiti, managing the country’s potable water system.)

KJ. All sorts of organizations, national and international, have been focusing on improving construction practices in Haiti since the earthquake, a few years ago now. Is construction getting easier? Have you noticed improvements?

LS. I’ve been here three years myself. What I notice is not so much a change in the contractors, but a change in the staff engineers that we hire. Some of them were always good, but in the beginning it was difficult to find construction management staff that really knew what to look for. When you’ve been educated in a way that’s not up-to-the-minute leading practices, you have to learn that on the job… we all have to do that, realistically. So the level of the engineers has been what’s improved most for me.

I think contractors, regardless of where you are in the world, are up against the same problem: they often bid lower to get the job, and when you get on site you get slapped with a lot of change orders to try and make up cost deficits and things that weren’t taken into account. In Haiti there’s always a deficit of materials that contractors can use as a reason for not getting something done on time or to the quality you’ve asked for. And that’s a real problem.

KJ. How much are you working on sanitation these days?

LS. I’m not up to my eyes in it anymore! A lot of the groundwork that I did with Architecture for Humanity has built a basic understanding of all the parameters to which you need to design here. Those interventions were a lot smaller, because AFH’s schools were smaller. Here I have sanitation systems that should be almost industrially managed due to the number of students that need to be accommodated on the site. As a result we have to look at the problem very differently.

KJ. Give me some numbers – how many students are we talking about?

LS. One of the schools has 2600. One of them has 4000. Another one has 2300, another 1400, the other has 800.

KJ. FOUR THOUSAND KIDS IN ONE SCHOOL?

LS. Yeah, and the site is tiny tiny. It’s an urban site. And the best part of all is that we had to somehow relocate them for the construction work – that’s going to be our biggest challenge.

KJ. So you’re working in multiple storeys…

LS. Ideally it would be a three- to four-storey response, but it’s not going to be. That’s partially because there is a reticence by the Ministry of Education in general to build higher than two storeys. They’ve been nervous about that since the earthquake, understandably.

We have structural engineers working for us that are more than capable of providing a four storey solution, but we had to divide up the project to allow somebody else to build part of it, and they’re building to the MOE request of two storeys. It’s not the ideal response, architecturally, to the site, but there are too many other factors that limit the design.

KJ. Speaking of ‘the industrial scale,’ how does designing a project that size work?

LS. We’re focusing on classrooms and sanitation. They’re huge schools, and we don’t have the budget to provide everything requested, so we pare down to necessities. Although in some cases a necessity is maintaining an auditorium, as some of the schools double as exam centers. Point being, there are certain aspects of the design brief that go beyond just classrooms. In terms of sanitation: for each of our projects, we are using a different system. Sanitation in schools here has to be designed as a whole system and is in fact a very contextual issue.

Ecole Immacule de Conception, for instance, is a “congressional school” they call it – it’s a public school part funded by the Catholic Church, and run by sisters. We’re putting a biodigester system in there. That’s in conjunction with a company called Sistema BioBolsa. They work out of Mexico on agricultural systems normally but they’ve been putting in a few systems here – one with Food for the Poor, another for a hospital in Cange…it’s the best biodigester system that I’ve seen in terms of its ability to produce gas.

The reason we chose that system there is because there’s a bit of room on the site that will allow us to extend the system into a garden. The landscape scheme allows waste management to happen entirely on site. There is no municipal sewage system bar the waste being trucked out so we try to manage much of the waste on site where viable. They also are a primary school. All public primary schools in Haiti are obliged to provide food for the kids, so there’s already a kitchen on site where they cook every single day. Hopefully the gas can augment that system.

The problem with all bio-digesters, which use human waste, is they don’t produce enough gas to manage all of the cooking needs of a school. This bio-digester is more technical in terms of the installation and is a bit more fragile. What they use is a very strong plastic geo-membrane bag, and all the breakdown of waste happens in that system. No oxygen gets in so the anaerobic process is very efficient. (One of the problems bio-digesters faced in Haiti is that a lot of the concrete leaked, allowing air to get into the mix.)

KJ. For sake of comparison, AFH’s Ecole Elie Dubois has a biodigester, but that’s a concrete system, so less efficient?

LS. In theory yes although I can’t speak about that system directly as I have had no follow up in terms of the monitoring. For me that makes the bags a selling point. The big weakness is the bags are more vulnerable-ultimately plastic breaks down in the sun over time. To prevent that we put a black blanket over top. That increases the heat, which is also very important – the more heat the bags have, the better they function. Having said that the plastic lasts easily 50 years – but if you come along with a giant knife and slash it open, they’re done for.

We’re also pouring concrete trenches with a metal grate cover to hold the bags and isolate them from the students. The bags will be covered with a metal deck so people can walk over them yet prevent damage. This school has 800 students.

KJ. So a biodigester is a good system for smaller school, and offsets kitchen gas needs by…a percentage.

LS. One of the things that’s good from our point of view is Alex Eaton from Sistema Biobolsa will be monitoring the amount of gas that’s produced. With all of these systems there’s a bit of an experimental nature, and human poo doesn’t create as much gas as animal poo.

KJ. Gas is one byproduct; would fertilizer be another?

LS. The “garden”–there will be a trench at the end that will be planted as part of the treatment system. Soil is actually very good at taking up microorganisms, when done correctly. Here you can plant things like banana trees (not so much vegetables), and the planting becomes part of the refinement system. Banana trees love nitrogen!

KJ. Very cool. What other systems are you looking at?

LS. In Jacques Premier we are planning on upgrading the septic system there; that’s what was existing, and we’ll use that for a low-impact solution. It was cheaper to rehabilitate and use existing toilets. The key issue now is managing the water.

All our public school projects were equipped with septic systems that were non-functional when we initially assessed them. Literally there’s not one school that I visited that had a functioning septic system, even though the infrastructure was installed. There’s no water. I don’t know what people did–some of them were pretty vile and some of them were shared with camps on the same school site.

So one of the things we’re trying to do as part of that is work on maintenance and operational plans with the school directors. The mission is twofold: first, to get the school direction to understand how their school functions and to know what aspects need to be taken care of and how to take care of them; second, because they’re all public schools we want to present the financials back to the Ministry of Education so they can be greater involved in the management. The MOE suggested the school directors show them the financial issues so they can help address them.

KJ. So you’re looking at making these septic systems function by incorporating water. Could you use rainwater for that?

LS. The thing is with the septic system, even with low flush toilets you’re never going to collect enough rainwater to manage the system. So we are putting in as much rainwater collection as we can, but ultimately that will have to be augmented from other sources.

That’s part of the contextual issue. Some of these schools have connections to the DINEPA water system – to the public main system. In those instances it’s okay for us to consider a water-based system. In other cases, we’re putting in as much rainwater as we can…there’s one site, Ecole Charlotin Marcadieu, in Croix-des-Bouquets, where we’re actually putting in a pit latrine. The site’s tiny, there are no water resources whatsoever, and the management of the school isn’t as robust as in other cases. There we’re putting in a water reservoir and a pump to handle hand washing, but the latrine system will have to be emptied out by truck the way that it normally is.

KJ. I hear a lot about bagasse…under what circumstances would a bagasse system be successful?

LS. We don’t use any composting system, due to the scale of the projects. Bagasse is a byproduct of the sugar cane industry and widely available in Haiti. It’s a fibrous dry material often used here as the carbon element in composting. AFH used bagasse in Pele, and that school, 2000 kids. The management levels for that size of system are kind of huge. It’s not impossible; at Ecole Charlotin Marcadieu we thought about using a composting system, but opted instead for something people knew how to use.

KJ. This priority of familiarity brings it back to that Santo charrette, where people were like “what is this weird sh*t that you’re proposing?” …No pun intended. Are people cool using things like biodigested gas? How do you approach that?

LS. That all depends on the school direction. Before we made the proposal at Ecole Immacule de Conception we brought two of the school’s sisters down to see a prototype in Haiti Communitere – to see their prototype biogas system and how it worked. They loved it so much they wanted to put it in other projects they knew of up North. That was wonderful to see.

In our partnership with Norwegian Church Aid we brought out all the school directors to see their biodigesters in Leogane. In those communities there are some people that lectured ME about sustainability and the environment and recycling and my heart skipped a beat, “OMG this is amazing!” In the context of Leogane, they managed a lot of community agricultural waste in the system as well, so their biodigestion probably functions at a higher efficiency. That being said, NCA have also learned a great deal over the last few years, and have adapted their interventions accordingly.

KJ. Last time we spoke about all this, in 2012, we just learned about the Sustainable Sanitation Conference summit. I recently stumbled upon notes from those meetings. What ideas drawn from those sessions have been put in practice?

LS. The summit was interesting because it brought together DINEPA with a lot of sustainable sanitation players in Haiti. I met Alex from Sistema Biobolsa there. The bottom line was the acknowledgement that some mistakes were made with sustainable sanitation systems in Haiti in the past, and the result has generated quite a bad reputation. Changing that is very difficult. Anybody working in Sustainable Sanitation is working slowly and wanting to do it right. The general feedback from the meetings is we needed more research and more definitive prototypes to make sure we’re doing things right.

KJ. Then you guys are fully participating in that mission.

LS. One of the things I really wanted to talk about was Lycee Jean Marie Vincent in Tabarre, our biggest school in terms of classroom intervention for Islamic Relief. We’re partnering with NCA who have decided to install an Anaerobic Baffle Reactor, which provides us with more confidence in its biological treatment than, say, a standard fully-mixed biodigester, NCA have been drawing on their experiences in Leogane and Port-au-Prince to pilot this new approach in Haiti.

Jean Marie Vincent School, under construction. Image by Lisa Smyth

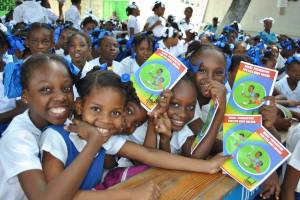

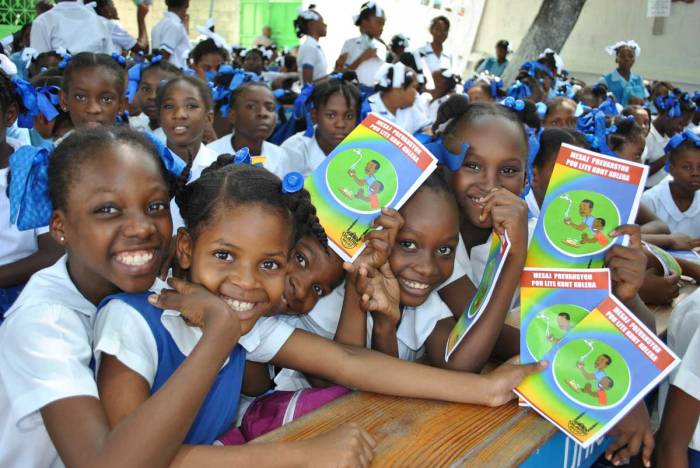

Jean Marie Vincent School, under construction. Image by Lisa Smyth From a handwashing workshop held by Islamic Relief with UNICEF. Image by Lisa Smyth

From a handwashing workshop held by Islamic Relief with UNICEF. Image by Lisa Smyth

KJ. Adam Salzman showed me the ABR that MASS is building for the cholera clinic.

LS. I’d be curious to see it – I keep meaning to go visit their project. Is it finished?

KJ. This was last October. The ABR looked finished. It looked like a submarine breaching, there’s not much to it. But maybe there’s everything to it.

LS. Yeah.

KJ. So the direction things are heading in, it’s all case by case.

LS. Precisely. Some projects require less intervention, some are absolutely under-resourced, just by the remoteness of the school, and others are more tied to infrastructure.

For our water-based systems, where there’s already a proper reservoir and a connection with DINEPA, water loads are less of a problem, but we are proposing a communal flush toilet – meaning there’s one point of flushing managed by someone in the school instead of every toilet being flushed by the students. A few months ago I spoke with someone at DINEPA who admitted their move was towards communal flush toilets – they’re kind of encouraging them. They’re water-based (more “modern”), but use less water in the school.

KJ. By ‘modernity’ you mean…

LS. In terms of the actual toilet installations we’re aiming to put in ceramic dry toilets, if we can find them. Ceramic keeps it looking like a modern interface, not just a seat slapped onto a concrete hole. But all the toilets drop into two flush channels underneath the toilet block – the channels are quite large and at the end of each building there’s a raised water tower flushing the whole thing out at intervals.

KJ. DINEPA’s a huge player in this whole thing.

LS. The people in there are pretty great. The department just isn’t big enough to deal with all of the issues country-wide. The sanitation problem is huge. We’ve only been talking about sanitation issues in schools in greater Port-au- Prince!

KJ. Project in the future a little bit – any awesome things to happen in 2014? Any papers to come out of all this research?

LS. For us the main thing is to finish these systems and get them running. Alex is going to start testing; Anthony has a long-term two-year management and monitoring operation in place for Lycee Jean Marie Vincent. Once these things are done, then the real work starts in terms gathering the findings.

For me, I’m really focusing on trying to finish these four schools. It’s not easy; “nearly finished” in Haiti can go on for months and months. We’re pursuing LEED for one of the schools–it’s a mammoth task and we’re not sure it’s possible. There are a lot of things we need to tidy up first to make that a reality. It’s attempting the impossible.

What’s the saying? “Hard things take a long time; impossible things take a bit longer.”